We rally their teams in a new organization

To rally on a project, each team member needs to feel like a key player and therefore it is necessary to let him take initiatives. To do this and to leave some freedom, it calls for a lot of courage from the managers.

Teams need to be able to be proud of what they do. It is the managers’ role to create the conditions of this feat.

Even the best message will not replace the fact that it should be owned and driven by the manager. And yes, it does, sometimes, require a lot of courage.

Even if you don't know where the future might lead you, your teams need to know your great convictions to get there.

In life, there are two strategies: seeking results - first and foremost - or checking progress. The first might work if you have the best recruits and the ability to replace them whenever you want, the second works every single time, with all the teams and especially when it comes to creating a dynamic.

If a nice rational explanation was key to convincing anyone, getting people on board would be the easiest thing to do. In fact, there is a whole emotional part that comes into play.

To reflect on your issues, we resort to a lot of methods.

These 3 are particularly key to us

“The market is too competitive”

“It is not the right moment”

“I don't have time”

“It is my boss' role”

Dare enthusiasm

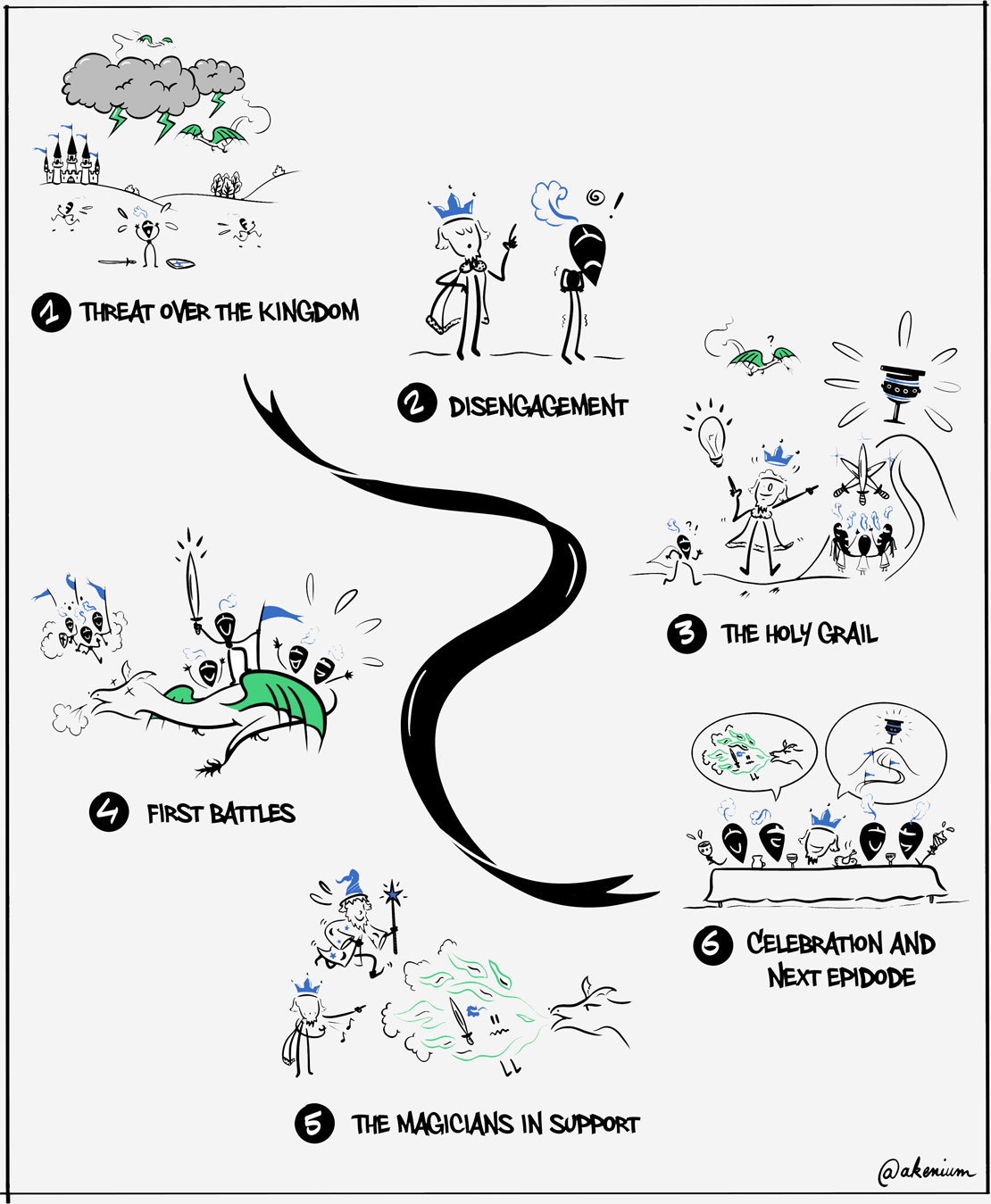

Faced with these, more or less, rational hurdles, we use the structure of tales to quickly interest the teams in a project, that seems (at first glance) to be far removed from their concerns, and to lead them into a dynamic made up of twists and turns, individual and collective pride.

From the structure of tales, we’ve uncovered 6 key learnings:

In order to rally your teams to the changes, it is necessary to be pragmatic and tactical :

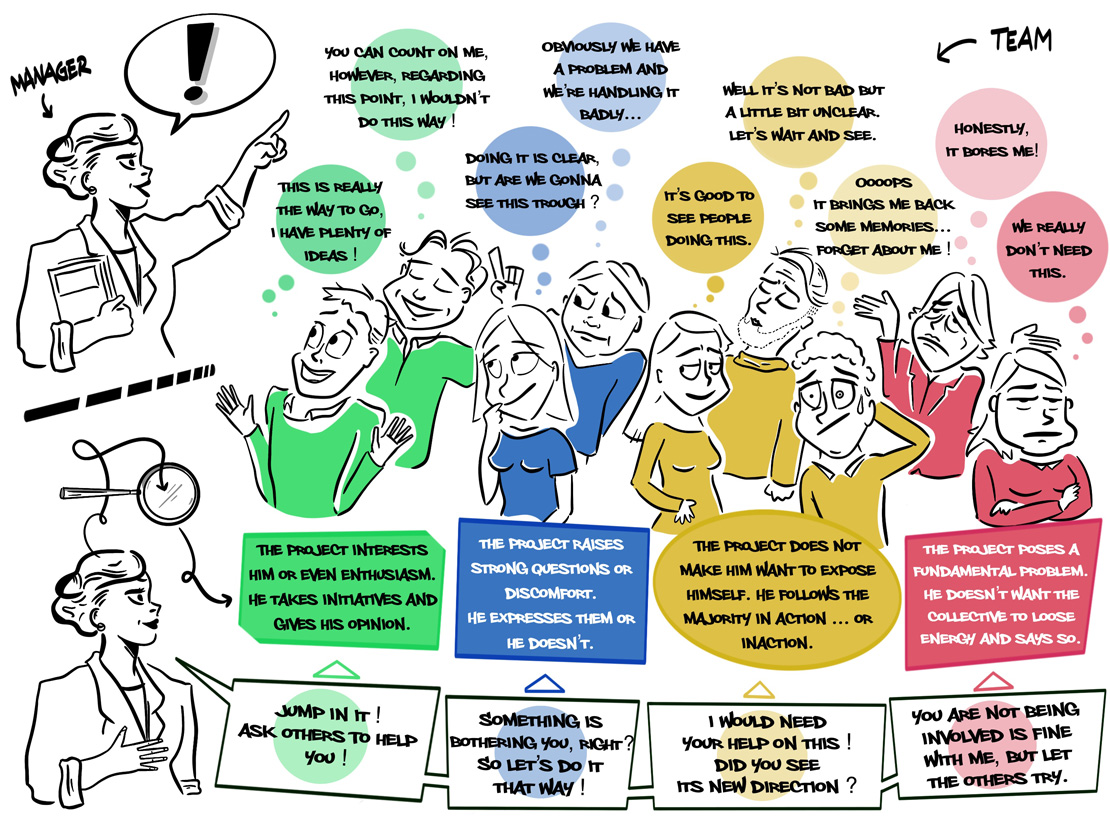

When a project is explained, each actor simultaneously generates 2 types of energy : a support energy (synergy) and a critical energy (antagonism), sometimes, up to opposition

The allies strategy is a tactic to stop a common bad reflex : focusing on opposition, trying to convince and forgetting to nurture those who are the most motivated, when it is their action which will be decisive !

To simplify : there are 4 main attitudes& tailored managerial answers to each

Sometimes as a manager you find yourself in stalemate without knowing how to get out of it. To achieve this and to enrich the Eastern philosophy, complementary to ours. And to do so, we use the Go game, the Asian counterpart of chess.

From this game we draw three main principles:

That is the long-term goal. It implies looking far ahead and it helps to put the short term into perspective when it does not correspond to the expectations. To see far ahead it also means to allow for some time to readjust if necessary and to consider time differently.

To gain time and efficiency, we connect the actions together and then the actions are connected to the final purpose. It gives consistency and, above all, it optimizes the energy-result ratio.

It is the assumption that instead of fighting against one’s opponent, one fights for one’s purpose. It implies taking the events and the context as they are and not wasting energy struggling with them.

We write, a lot, about management techniques, current events, and even about artistic works !

Click here to read moreWe often publish, super interesting things, about management techniques, current events in our field, and even sometimes just for the sake of chatting !

Click here to listen